Top 10 Manufacturing Vending Machines for Your Business Success

In the fast-evolving landscape of modern business, the integration of technology into operational processes has become essential for success. One area experiencing significant growth is the use of manufacturing vending machines, which streamline inventory management and improve workforce efficiency. According to a report by IBISWorld, the vending machine manufacturing industry has seen a steady increase, with an annual growth rate of approximately 3.2% over the past five years. This upward trend is indicative of a broader shift towards automation in various sectors, allowing businesses to reduce overhead costs while maximizing productivity.

Manufacturing vending machines serve as a solution not only for employee needs but also for effective inventory control, enabling businesses to dispense tools, parts, and other supplies on-demand. A survey conducted by the National Automatic Merchandising Association indicates that companies that have implemented these systems have reported up to 30% reduction in operational costs due to minimized inventory wastage and improved accessibility. As more organizations recognize the inherent advantages in adopting manufacturing vending machines, exploring the top options available can significantly enhance business performance and contribute to long-term success.

Importance of Vending Machines in Modern Manufacturing Businesses

In today’s fast-paced manufacturing environment, vending machines have emerged as essential tools that enhance operational efficiency and employee satisfaction. By providing instant access to snacks, beverages, or essential tools, vending machines can significantly reduce downtime. Employees no longer need to leave the workplace for breaks, allowing them to stay focused and productive. This arrangement not only boosts morale but also fosters a healthy work-life balance by ensuring that team members have easy access to necessary provisions throughout the day.

Tips: When selecting vending machines for your manufacturing facility, consider the specific needs of your workforce. Offering a variety of healthy snacks, beverages, and even items like safety gear can cater to diverse preferences and enhance overall employee wellness. Additionally, ensure that the machines are stocked regularly and maintained properly to avoid any disruptions.

Moreover, vending machines can be tailored to fit operational workflows. For instance, incorporating smart technology into vending solutions can facilitate inventory management and allow for real-time tracking. This means businesses can avoid shortages and streamline supply chains, significantly impacting productivity. Investing in these systems not only improves day-to-day operations but also contributes to the overall success of the manufacturing enterprise.

Types of Manufacturing Vending Machines Available in the Market

Manufacturing vending machines have gained popularity as versatile solutions for businesses looking to enhance efficiency and streamline operations. Various types of these machines cater to different needs within the manufacturing sector, each offering unique functionalities. Traditional vending machines, often found in workplaces, can be equipped to dispense snacks, beverages, and personal protective equipment (PPE). These machines provide employees easy access to essentials while minimizing downtime, promoting a more productive environment.

In addition to conventional vending machines, advanced options like smart vending machines are reshaping the landscape. These machines utilize technology to track inventory levels in real-time, enabling automatic restocking notifications and sales analytics. Furthermore, they can accommodate a diverse range of products, from tools and maintenance supplies to specialty items required in specific manufacturing processes. Another innovative variant is the custom vending machine, which can be tailored to meet the specific demands of a facility, ensuring that essential items are always available at the point of need. By investing in the right type of manufacturing vending machine, businesses can significantly enhance operational workflow and employee satisfaction.

Key Features to Consider When Choosing a Vending Machine

When selecting a vending machine for your business, it’s essential to consider several key features that can significantly impact your success. First and foremost, consider the machine's capacity and configuration. Depending on your location and target audience, you'll want a machine that can accommodate a variety of products and has a sufficient stock capacity to minimize refilling needs. The ability to customize the product selection will enable you to cater to the preferences of your customers, increasing the likelihood of sales.

Another crucial feature is the payment system. Today’s consumers expect convenience, so opting for a vending machine that supports multiple payment options, including cash, card, and mobile payments, is vital. This flexibility allows you to attract a broader range of customers, especially those who prefer cashless transactions.

Additionally, look for machines with user-friendly interfaces, as an intuitive design can enhance the customer experience and encourage repeat business. Lastly, consider machines equipped with remote monitoring capabilities, allowing you to track sales and inventory in real-time, ultimately helping you make informed decisions about product restocking and management.

Top 10 Manufacturing Vending Machines Reviewed

In the modern business landscape, vending machines have evolved beyond mere snack dispensers to sophisticated platforms for diverse products and services. The top manufacturing vending machines offer reliable and efficient solutions, catering to the varied needs of industries. From automated food and beverage options to machines that dispense tools and safety equipment, these vending solutions can enhance workforce productivity and satisfaction. By providing easy access to essential items, businesses can reduce downtime and streamline operations.

When selecting a vending machine for manufacturing purposes, several features deserve consideration. Machines should prioritize durability and ease of maintenance, given the often harsh environments of manufacturing settings. Additionally, advanced technology such as touchless payment systems and inventory management capabilities is essential for optimizing the vending experience. These features not only improve user convenience but also help operators manage stock levels effectively, ensuring that workers have access to what they need when they need it. Ultimately, the right vending machine can play a crucial role in driving operational efficiency and supporting employee well-being in manufacturing environments.

Benefits of Implementing Vending Machines in Your Production Line

Implementing vending machines in your production line can significantly enhance operational efficiency and employee satisfaction. One of the primary benefits is the convenience they offer. Workers can access snacks and beverages during breaks without leaving the production area, minimizing downtime and keeping morale high. This easy availability of refreshments helps to promote productivity and can reduce the likelihood of fatigue during long shifts.

Another advantage is the variety and customization these machines can provide. Businesses can tailor their selections to cater to the preferences and dietary needs of their workforce, ensuring that employees have access to healthy options as well as traditional snacks. This not only supports better nutrition but also demonstrates a company’s commitment to employee well-being. Additionally, vending machines can streamline inventory management, reducing waste and costs associated with traditional cafeteria systems, ultimately contributing to the overall success of the business.

Related Posts

-

Why Combo Vending Machines Are Revolutionizing Snack and Drink Sales

-

Unlocking Success: Innovative Strategies to Boost Your Vending Machine Business in 2024

-

10 Essential Tips for Choosing the Best Vending Machine for Your Business

-

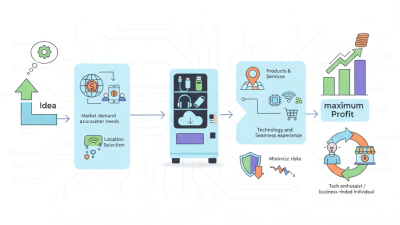

How to Start Your Own IT Vending Machine Business for Maximum Profit

-

How to Start a Full Vending Machine Business and Maximize Profits

-

The Ultimate Guide to Starting a Vending Machine Business in 2025