What is Vending Machine Maintenance and How to Ensure Its Efficiency

In the bustling world of automated retail, ensuring optimal performance of vending machines is crucial. As expert in vending machine maintenance, John Smith emphasizes, "Regular upkeep not only enhances operational efficiency but also prolongs the life of the machines." This insight highlights the importance of a systematic approach to vending machine maintenance, which not only covers the physical condition of the machine but also its inventory management and customer service elements.

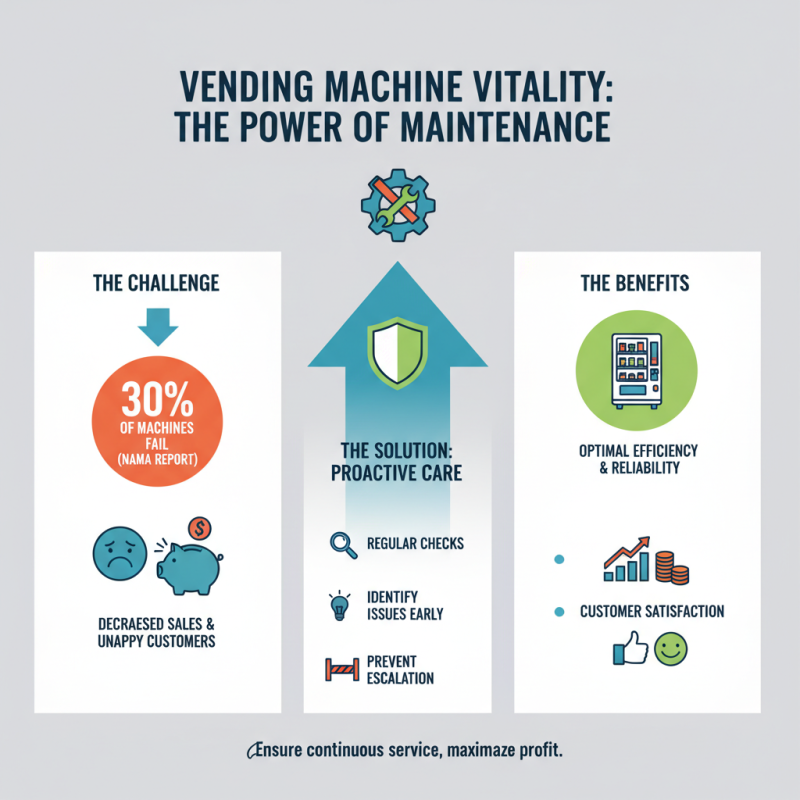

Vending machine maintenance encompasses a range of tasks from routine cleaning to troubleshooting technical issues. Neglecting these responsibilities can lead to frequent breakdowns, decreased customer satisfaction, and ultimately, loss of revenue. Implementing a proactive maintenance schedule can mitigate these risks, ensuring each machine operates at peak efficiency. In today’s competitive market, it is essential for operators to prioritize vending machine maintenance as an integral part of their business strategy, thus maximizing productivity and profitability.

By investing time and resources into effective maintenance procedures, vending machine operators can not only maintain their equipment but also create a reliable reputation among customers. In the end, the success of any vending operation hinges on the reliability and efficiency of its machines, underscoring the vital role of diligent vending machine maintenance.

Understanding Vending Machine Maintenance: An Overview

Vending machine maintenance is a crucial aspect for operators seeking to maximize efficiency and customer satisfaction. Regular upkeep ensures machines are stocked, clean, and functioning correctly, which can significantly affect sales performance. According to a study by IBISWorld, the vending machine industry's revenue in the U.S. reached approximately $25 billion in 2022, underscoring the importance of maintaining these machines to capitalize on such economic potential.

An effective maintenance strategy typically includes routine inspections to monitor machine performance and identify potential issues before they escalate. This may involve checking internal components, replenishing stock, and cleaning surfaces to prevent contamination. The National Automatic Merchandising Association (NAMA) indicates that well-maintained machines can enhance user experience and contribute to a higher return on investment, with machines that receive regular servicing reporting up to 20% increased sales. Additionally, technicians should utilize data analytics to understand usage patterns and adjust maintenance schedules accordingly, ensuring optimal machine performance and meeting customer demands.

Key Components of Vending Machine Maintenance Procedures

Efficient vending machine maintenance is crucial for ensuring optimal functionality and maximizing revenue. One of the key components of effective maintenance procedures is regularly scheduled inspections, which should ideally occur bi-weekly or monthly depending on machine usage. According to a report by the National Automatic Merchandising Association (NAMA), proactive maintenance can reduce operational costs by up to 30%, thereby enhancing the overall profitability of vending operations. During these inspections, technicians should check critical components such as coin mechanisms, bill validators, and inventory levels, ensuring all parts are functioning correctly to minimize downtime.

Another vital aspect of vending machine maintenance is cleaning and sanitization. Regular cleaning of machine surfaces, dispensing areas, and internal compartments not only maintains product quality but also extends the life of the machine. The International Vending Alliance recommends a deep clean at least once a month, supplemented by quick daily wipe-downs to remove dust and residue. Failure to maintain cleanliness can lead to operational issues and potential health violations, with studies showing that neglected machines can harbor bacteria, decreasing customer satisfaction and damaging brand reputation. By implementing robust maintenance protocols focusing on these key components, operators can enhance machine reliability and customer experience.

Regular Cleaning and Inspection Practices for Vending Machines

Regular cleaning and inspection practices are essential for maintaining the efficiency of vending machines. Over time, these machines can accumulate dirt, debris, and spills, which not only detract from their appearance but can also affect their functionality. Routine maintenance should involve a thorough cleaning of both the exterior and interior components. This includes wiping down surfaces with a mild disinfectant, ensuring the glass is clean for visibility, and regularly checking for expired or outdated products.

Tips for effective cleaning include scheduling weekly or bi-weekly cleaning sessions and keeping a maintenance log to track when each machine was last serviced. When inspecting the internal mechanisms, ensure that payment systems are functioning properly and that the delivery system is unobstructed. This helps to prevent jams and customer complaints. Regular inspections also allow you to monitor inventory levels, ensuring that products are always available for customers.

In addition to cleaning, it’s crucial to monitor machine performance and troubleshoot any issues that arise promptly. This may involve checking the power supply, ensuring proper temperature control, and testing the keypad or touch interface. Keeping tools and spare parts on hand can facilitate quicker repairs, leading to less downtime and improved customer satisfaction. Prioritizing these practices will ensure your vending machines remain functional and efficient, providing consistent service to users.

Troubleshooting Common Vending Machine Issues for Efficiency

Vending machine maintenance is crucial to ensure optimal efficiency and service reliability. One of the most common issues encountered by operators is machine malfunctions, which can lead to decreased sales and customer dissatisfaction. According to a report from the National Automatic Merchandising Association, approximately 30% of vending machines experience technical failures that can interrupt service. Regular maintenance checks can significantly reduce the impact of these failures by allowing operators to identify potential issues before they escalate.

Common problems such as product jams, card reader malfunctions, and improper temperature control can often be resolved with basic troubleshooting techniques. For instance, regular cleaning of sensors and check-ups on product loading can prevent jams caused by misaligned items, which the report highlights as a primary cause of downtime. Additionally, ensuring that payment systems are properly updated and secure can mitigate communication errors that lead to transaction failures. By investing time in troubleshooting and routine maintenance, operators can bolster the efficiency of their vending machines and enhance the overall customer experience, ultimately leading to better profitability.

Best Practices for Enhancing the Longevity of Vending Machines

Maintaining vending machines is crucial for ensuring their efficiency and longevity. Regular maintenance can prevent major technical issues and reduce operational costs. According to industry reports, vending machine downtime can lead to a loss of revenue, with estimates suggesting that businesses can lose up to 20% of their potential income during periods of equipment failure. To mitigate these losses, employing best practices in vending machine maintenance is essential.

One effective practice is to establish a routine cleaning schedule. This includes removing food debris, sanitizing surfaces, and checking expiration dates on inventory. A proper clean not only enhances machine aesthetics but also ensures the safety and satisfaction of consumers. The National Automatic Merchandising Association (NAMA) recommends that machines be serviced at least once a week to keep them running smoothly. Additionally, regular inspections of electronic components and mechanical parts can help identify wear and tear early, reducing the risk of unexpected breakdowns.

Another critical aspect is to monitor the stock levels and sales performance regularly. An analytical approach to picking and restocking inventory can optimize sales and minimize product spoilage, which is particularly important in the perishable goods segment. Reports indicate that vending machines with effective inventory management can increase profitability by up to 15%. By adopting these best practices, operators can enhance the longevity of their vending machines while maximizing their operational efficiency, leading to sustained profitability in a competitive market.

What is Vending Machine Maintenance and How to Ensure Its Efficiency - Best Practices for Enhancing the Longevity of Vending Machines

| Maintenance Activity | Frequency | Benefits | Tips |

|---|---|---|---|

| Restocking Products | Daily | Ensures availability and customer satisfaction | Use inventory management software to track stock levels |

| Cleaning Interior and Exterior | Weekly | Prevents buildup of dirt and grime | Use non-abrasive cleaners |

| Checking for Mechanical Issues | Monthly | Maintains functionality and reduces downtime | Document issues and repairs |

| Testing Payment Systems | Weekly | Ensures transactions are processed smoothly | Check all payment methods including cash and card |

| Updating Software | Biannually | Improvements in security and functionality | Follow manufacturer updates for software |

Related Posts

-

Top 10 Essential Tips for Finding the Best Vending Machine Fixer Professionals

-

Essential Tips for Becoming a Successful Vending Machine Fixer

-

Top 10 Vending Solutions Driving 30 Percent Growth in the Industry

-

Transform Your Workplace with Cutting-Edge Coffee Vending Machines: Boost Employee Satisfaction Today!

-

Innovative Vending Solutions Transforming Workplace Nutrition and Beverage Access

-

10 Essential Tips for Maximizing Profits with Snack Vending Machines